Like any pollutant present in the ambient air, water vapor is drawn in and concentrated during the compression of the air. At the outlet of the compression block, the high temperature of the air keeps the humidity in vapor form. Downstream of the compressor, as soon as the air cools down, the humidity condenses and the water appears in liquid form called condensate. In our climate, a 120 m3/h compressor generates about 1 liter of condensate per hour. If the compressor is lubricated, polluting hydrocarbons will be mixed with this condensate.

The solutions

| Issues | Specialized solutions | |

| Step 1 | How to dry compressed air ? | Refrigeration or adsorption dryers |

| Step 2 | How to remove liquids and filter aerosols, droplets and particles? | Filters PHENIX : - Cyclone separators - Pre-filters (1μm) - Oil separators (0.01μm) and filters elements |

| Step 3 | How to evacuate the condensate? | Condensate drain |

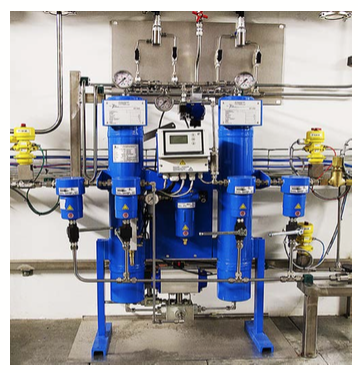

| Step 4 | How to purify the condensates to discharge them? | PURO ELITE separator Residual oil content less than 10 mg/litre |