Adsorption dryer - MWE series

| Manufacturer | Partenair |

| Categories | Compressed air treatment, Dryers for compressed air circuits: refrigeration, adsorption, membrane dryers, Adsorption dryers |

|

Water (Vapor)

Dew point -40°C

|

Classe iso : 2

9876543210

|

| Document to download | |||

| G005_Secheur_MWE_PresentationA3 |

Optimal energy efficiency

The MWE series of dryers is mainly intended for applications with 24 hour operation.

It is particularly economical to use thanks to its internal heating system using multiple low-

power heating elements per column.

These resistances, out of contact with the desiccant, take place in finned tubes responsible

for ensuring a homogeneous distribution of the calories in the desiccant beds.

This technique provides maximum efficiency and the lowest operating costs on the market.

An optional energy saver (see below) makes it possible to further reduce energy

consumption in the case of fluctuating flows or less than the nominal capacity.

The range includes 11 models and covers flow rates between 245 and 4300 m3 / h

- Standard pressure dew point: - 40 ° c (ISO class 8573-2001: 2)

- Resistors installed in finned tubes, no contact with the desiccant, better heat distribution.

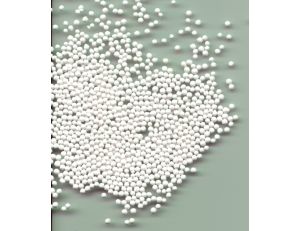

- DELSORB HQ A4 spherical desiccant, limited attrition, low dust production, excellent temperature resistance.

- Dry air cooling, no humidity before inversion of the cycle, no pollution of the desiccant by ambient air.

- Low power consumption for regeneration.

- Low noise level. (<70 DbA)

- 2 temperature control thermostats per tank.

- Automatic end of cycle stop with compressor stop signal.

- Compliance with the pressure equipment directive (97/24 EEC)

- Cycle control by SIEMENS programmable controller.

- Efficient exhaust mufflers with anti-burst valves.

- E8 energy saver optional.

* Select the generic if you don't know which model to choose. The sales department will contact you to determine the appropriate model.

(*) Nominal dryer capacity according to DIN ISO 7183, pressure dew point -40 ° C

(**) The capacity of the dryer is based on the capacity of the air compressor at 20 ° C, 1 bar (a)

Due to their low consumption of compressed air (<3%), MWE calorific regeneration dryers

are particularly suitable for installations with a large or continuous flow.

Proven for over 30 years, the DELTECH MWE range of adsorption dryers is the only one to

offer a homogeneous and direct distribution of regeneration energy in desiccant beds.

Each tank has multiple heating elements installed in individual finned tubes. These fins avoid

any hot spot in the columns and distribute quickly and optimally the energy necessary for

the regeneration of the desiccant. 2 thermostats per tank regulate the regeneration

temperature in order to optimize electricity consumption as much as possible.

The tanks are cooled by dry compressed air, preventing contamination of the desiccant by

humidity or environmental pollution. A programmable controller manages all of the cyclic

functions which are visualized by indicator lights on the control box.

An advanced energy saver (E8) is also available as an option.

Detailed specifications

| Min. Operating pressure |

4 bars |

| Max. Operating pressure | 10 bars |

| Min. compressed air temp. | 5 °C |

| Max. compressed air temp. | 50 °C |

| Min. ambient temp. | 5 °C |

| Max. ambient temp. | 50 °C |

| Power supply | 400V / 3 ph / 50Hz |

The following factors allow you to select the dryer when the operating conditions are

different from the standard conditions

| Coefficient for different pressures at inlet (bar) |

|||||||||||||

| Bar | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Correction factor | 0.63 | 0.75 | 0.88 | 1.00 | 1.12 | 1.25 | 1.37 | Contact your distributor for a selection | |||||

| Coefficient for different inlet air temperatures in ° C |

||||||

| °C | 5 | 30 | 35 | 40 | 45 | 50 |

| Correction factor | 1.00 | 1.00 | 1.00 | 0.77 | 0.59 | 0.46 |

| Example | Calculation | |||

| Capacity | 900 m3/h | Corrected capacity for 35°C, 7 bar = 900/ (1,37 * 0,59) =1113 m3/h |

=>MWE 385 dryer is adapted. |

|

| Inlet air pressure | 10 bar | |||

| Inlet air temp. | +45°C | |||