PLH series dryer - pressure up to 50 bar

| Manufacturer | Partenair |

| Categories | Compressed air treatment, Dryers for compressed air circuits: refrigeration, adsorption, membrane dryers, Refrigerated compressed air dryers |

|

Water (Vapor)

Dew point +3°C

|

Classe iso : 4

9876543210

|

| Document to download | |

| 25Sécheurs_PLH |

Medium pressure range

The PLH series refrigerated dryers is designed for compressed air networks up to a pressure of 50 bars needing a pressure dew point of +3ºC.

They are equipped with stainless steel plate heat exchangers. These heat exchangers offer a better resistance and take up less space than traditional ones.

The cooling circuit is regulated by a proportional valve, guaranteeing a dew point stability from 0 to 100% of the flow.

The range comprises 19 models covering flows of up to 5000m3/hr.

• 3ºC pressure dew point (ISO 8573-1:2001=4 class)

• stainless steel brazed plate heat exchanger

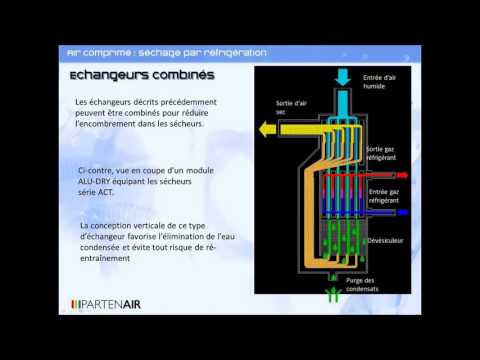

• vertical design of the heat exchanger, natural separation of the water through gravity, without risk of backflow

• condensate separator with stainless steel demister

• digital display of the dew point

• electronic controller with configurable remote alarm monitoring

• low energy consumption

• low clutter

• electronic condensate drain

* Select the generic if you don't know which model to choose. The sales department will contact you to determine the appropriate model.

(*) ISO 7183 - 20ºC 1 bar abs. for a pressure of 40 bar, compressed air 35ºC, ambient air 25ºC, pressure dew point +3ºC.

PLH: Medium pressure range

The PLH series refrigerated dryers is designed for compressed air networks up to a pressure of 50 bars needing a pressure dew point of +3ºC.

The thermodynamic circuit is designed around a robust stainless steel brazed plate heat exchanger. These heat exchangers offer a better resistance and take up less space than traditional ones.

A proportional regulation bypass valve offers a perfect stability to the cooling circuit and a constant dew point , without freezing risk, regardless of the dryer’s load.

The dew point is constantly displayed for a better control.

Detailed specifications

| Maximum service pressure |

50 bars |

| Max. compressed air temp. |

65°C |

| Min./Max. ambient air temp. |

+10 / + 50°C |

| Manufacturing code |

DESP 97/23 |

| Power supply (PLH 40 2 to PLH 130) |

240 / 1 / 50 Hz |

| Power supply (PLH 160 to PLH 500) |

400 / 3 / 50 Hz |

| Condensate drain |

Temporised solenoid valve |

| Necessary filtration |

5μ upstream |

| Refrigerant used (PLH 4 to PLH 22) |

R 134 A |

| Refrigerant used (PLH 30 to PLH 500) |

R 404 A |

| Condensator (standard) |

forced air |

| Condensator (optional) |

Water (PLH 75 and beyond) |

Correction factor depending on operating pressure

| Pressure | Bars | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

| Factron | x | 0.75 | 0.82 | 0.87 | 0.92 | 0.96 | 1.00 | 1.03 | 1.06 |

Correction factor depending on ambient temperature

| Temp. | °C | 25 | 30 | 35 | 40 | 45 | 50 |

| Factor | x | 1.00 | 0.98 | 0.95 | 0.90 | 0.88 | 0.81 |

Correction factor depending on compressed air temperature

| Temp. | °C | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 |

| Factor | x | 1.27 | 1.12 | 1.00 | 0.88 | 0.78 | 0.70 | 0.62 | 0.55 | 0.49 |

Correction factor depending on outlet air temp.

| Dew point | °C | 3 | 5 | 7 | 10 |

| Factor | x | 1.00 | 1.09 | 1.19 | 1.37 |