The different desiccants for adsorption air dryers

The desiccant is a solid and microporous material designed to adsorb the water molecules contained in the compressed air to dry it and thus lower the dew point.

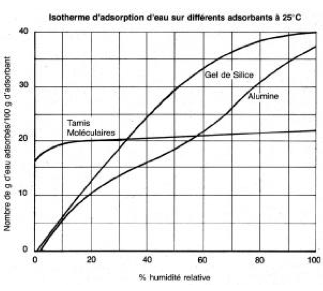

Three types of desiccant with different capacities are used to dry compressed air :

Aluminas - molecular sieves - silica gels

Molecular sieves provide good performance at humidities below 30%, whereas silica gels and aluminas perform better in high relative humidities.

The quality of the products is distinguished by several characteristics :

Shape : The uniform size and sphericity of the balls allows for more efficient flow distribution across the cross-section of the drying tower, minimises preferential gas passage through the desiccant bed during drying and thus provides better dew point performance.

Hardness : Resistance to crushing by the weight of the desiccant column.

Abrasion : Loss expressed as a % of weight, the lower the value, the less dust will be present.

Specific surface area : Expressed in m² per gram, the adsorption efficiency of the product is directly related to this value.