KONSO SMART Power meters

| Manufacturer | Partenair |

| Categories | Measure, Power meters for industrial machines |

| Document to download | |

| N261_KONSO-SMART |

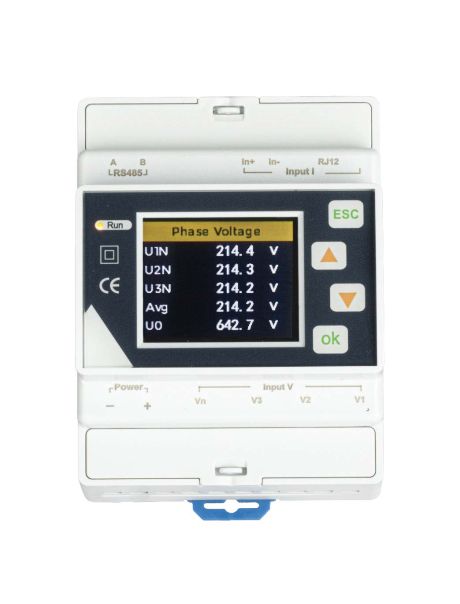

Intelligent power meter: KONSO SMART

The KONSO SMART range measures the accumulated power and energy consumption of three-phase electrical consumers, such as your compressors, dryers and oxygen/nitrogen generators.

APPLICATIONS

✓ Compressor energy monitoring:

Monitoring compressor power consumption enables you to analyse its energy efficiency and optimise its operation. By exploiting real-time data, operators are able to quickly identify any anomalies or loss of efficiency, enabling them to adjust operating parameters to improve overall performance while reducing energy expenditure.

✓ Energy management in industrial environments:

Real-time management of energy consumption enables industries to optimise their performance while controlling their expenditure. By studying consumption trends, it becomes possible to deploy targeted actions to save energy, generating substantial savings and strengthening the commitment to sustainable development.

✓ Industry and process control:

A stable power supply is essential to ensure the continuity and efficiency of industrial processes. By ensuring reliable energy monitoring, companies can anticipate failures, limit interruptions and maintain a high level of productivity while reducing the costs associated with unplanned stoppages.

✓ Renewable energies:

In solar and wind power installations, real-time monitoring of voltage and current is essential to maximise production efficiency. Thanks to its advanced measurement capabilities, the KONSO SMART stands out as a key device for monitoring, optimising and stabilising the production and distribution of renewable energy.

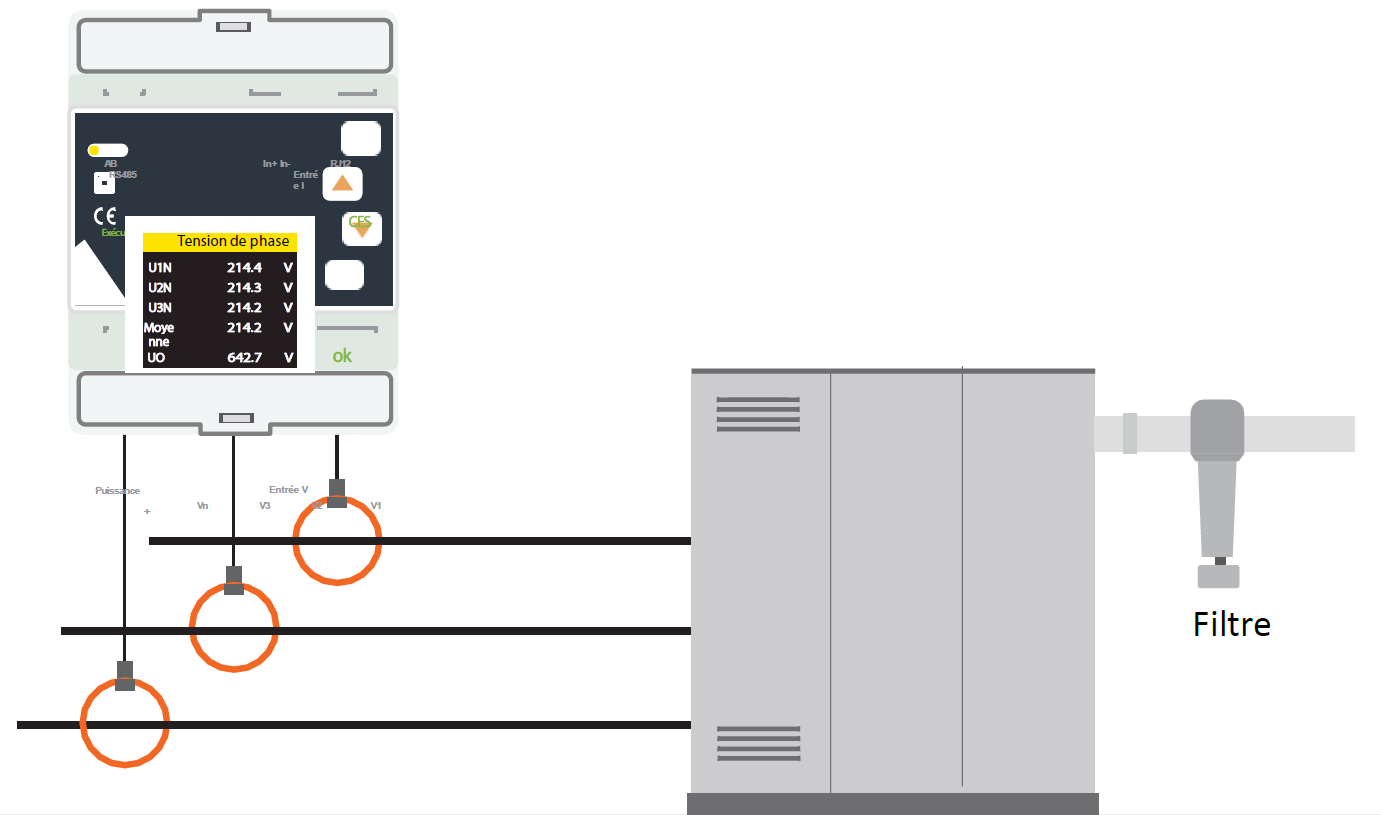

In this illustration above, a power and energy meter is installed directly in the compressor terminal box of the compressor. Rogowski current coils are easy to install, simply clamped around the power cables.

The voltage connection can be drawn directly from the compressor's electrical cabinet.

This not only identifies inefficient compressors, but also tells the compressed air operator what

what the real compressed air costs are.

* Select the generic if you don't know which model to choose. The sales department will contact you to determine the appropriate model.

Detailed specifications

| Phase voltage | L1, L2, L3, N, max 720 VAC |

| Power supply | 18-36 VDC, 3,5 VA |

| Clamps available | 200 A, 500 A, 1000 A |

| Power range | 100 A, 1 000 A ou 3 000 A |

| Exit | Modbus/RTU |

| Dimensions | 95 x 73 x 66 mm |

| Operating temperature | -25°C...-60°C |

| ACCESSOIRES | |

| MPU0130 | Set of 3 x current transmitters, 100 AAC, 30 mm diameter, 2 m cable with RJ12 connector |

| MPU0140 | Set of 3 x current transmitters, 1000 AAC, 100 mm diameter, 2 m cable with RJ12 connector |

| MPU0150 | Set of 3 x current transmitters, 3000 AAC, 150 mm diameter, 2 m cable with RJ12 connector |