Wine making is complex and requires a lot of experience and knowledge in the different stages of the wine making process.

In addition, the different wine varieties (white, red and sparkling wine), considerably influence the associated management and production process. The duration and intensity of the transformation of the must into wine (when alcoholic fermentation transforms sugar into alcohol) depends mainly on the temperature of the must, after the intrinsic properties of the grape.

It is therefore essential for the oenologist, on the basis of his or her own experience, to be able to manage this temperature precisely in order to obtain a wine with the desired characteristics at the end of the process.

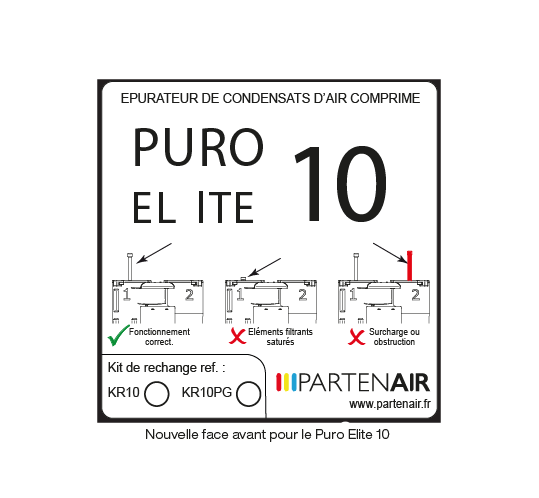

PARTENAIR chillers make it possible to control this important process with precision and ease, and to control the temperature of the tanks with extreme precision.

Considering the importance of temperature control for a high quality product, PARTENAIR offers several ranges dedicated to wine applications (Models: FRM/ FRD (10 to 100 kW), FRH (100 to 300 kW), FRX (280 to 1200 kW), designed in collaboration with internationally renowned manufacturers of wine production equipment and wineries

PARTENAIR chillers make it possible to improve the refrigeration process with precision and simplicity, by controlling the temperature of the tanks.

But the use of chillers is not limited to this: on request, it is possible to use the same equipment to cool wine cellars or buildings (tasting rooms, offices, showrooms, restaurants, bedrooms, etc.) during the summer, and to switch to heat pump mode to heat the premises during the winter.