Since the final air refrigerants are integrated into the compressors, there is a tendency to neglect this accessory, which is nevertheless essential for the proper functioning of the treatment chain and in particular the compressed air dryer.

However, a final forced air refrigerant is only effective if the temperature of the cooling fluid (ambient air) is sufficiently low because this type of refrigerant delivers a compressed air temperature higher by 10 to 12 ° C by relative to the temperature of the place.

Therefore, for installations subject to high ambient heat (above 30 ° C) it becomes necessary to consider the installation of a water-cooled refrigerant.

This refrigerant allows significant savings on the compressed air drying station :

- On the acquisition, because the dryer will not need to be oversized.

- On the farm, because the energy costs (electrical and/or pneumatic) will be greatly reduced (especially in the case of an adsorption dryer)

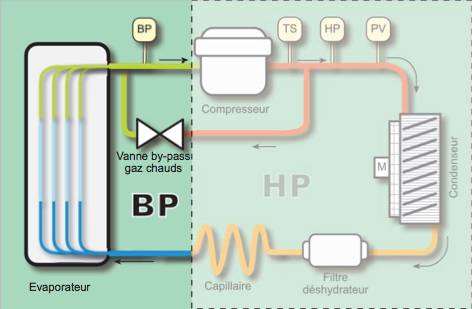

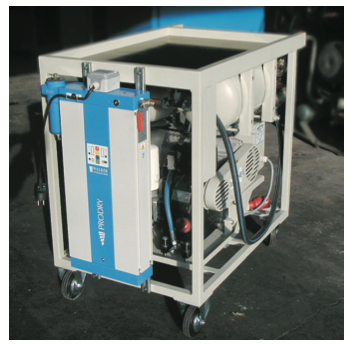

If the customer already has a chilled water circuit, installation is greatly facilitated, and water consumption can be optimized by installing a thermostatic valve controlling the flow of water required at the outlet temperature compressed air. (See photo above)

For a compressed air network with a large flow rate, if the customer does not have a chilled water circuit, the investment of a water chiller dedicated to the final refrigerant can be very profitable in the case of installation with an adsorption dryer.

Indeed, the resulting low operating cost obtained thanks to an energy saver makes it possible to quickly amortize (most often in less than a year) the necessary additional investments.