On-site nitrogen production chassis for wineries

Compact and mobile, designed specifically for wine applications

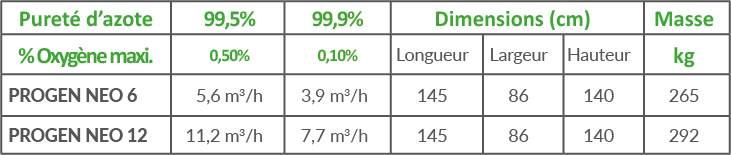

Nitrogen flow rate: 4 to 11 m3/h

Nitrogen purity: 99.5% to 99.9

Electrical connection: 230 V

Communicating touch interface

Easy to install

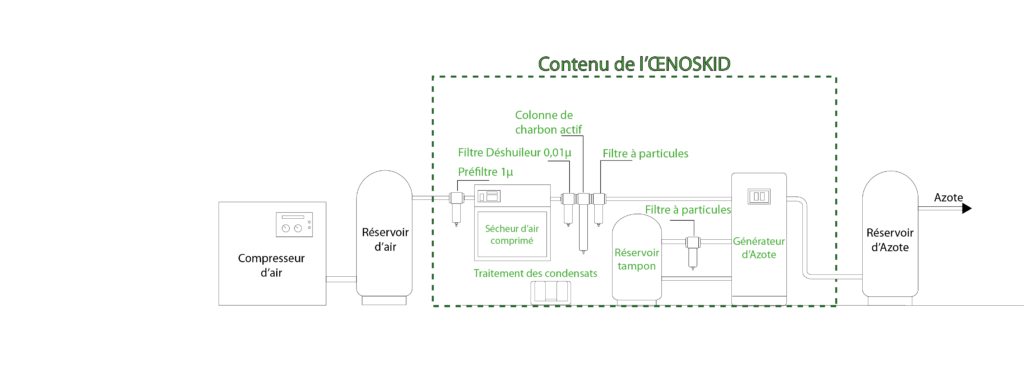

Simply connect your OENOSKID to a compressed air source and

air source and immediately produce your nitrogen on site.

Its compact design allows for easy installation, even in tight spaces

even in tight spaces, and at a lower cost.

Intuitive control interface

Control and access to the various functions of the generator is made easy by the large colour touch screen. The use of icons allows simple and intuitive navigation through the various menus.

Feed nitrogen

The nitrogen produced is certified food grade for contact with food as an additive E 941.

Rapid return on investment

The savings over traditional nitrogen cylinder supply provide a very rapid return on investment.

Eligible for FranceAgriMer aid

This nitrogen production skid is eligible for FranceAgriMer aid to reduce your investment costs.

Quality first

The mass flow controller guarantees the expected nitrogen flow and pressure. The oxygen analyser guarantees the required level of purity at all times.

Oxygen Analyser

The highly sensitive zirconium oxygen analyser probe offers an increased lifetime compared to traditional electrochemical probes.

Guaranteed performance

Decades of experience in P.S.A. adsorption technology guarantees a quality product. Each nitrogen generator is 100% factory tested before shipping to certify the flow rate and purity of the nitrogen produced.

Each skid is covered by a 2 year warranty.

Autonomy and reliability

Be autonomous for your nitrogen needs. Free yourself from the hassle, risks and constraints of managing, transporting and storing high-pressure gas cylinders.

ECO" mode, reduced operating costs

The generator has an automatic standby mode. It does not consume compressed air when your activity no longer requires a supply of nitrogen. The generator automatically resumes operation as soon as there is a new need for nitrogen is required.

Energy saving mode according to purity (optional)

Reduces compressed air consumption with an additional oxygen analyzer that extends cycle times when cycles when demand is less than the rated capacity without affecting the quality of the nitrogen supplied.

Web interface

A web portal, supplied as standard, allows remote control and monitoring of the nitrogen generator.

Traceability is ensured through the continuous recording of nitrogen purity. This data can then be retrieved via the web portal and also exported to a USB stick for viewing and archiving in Excel format.

Nitrogen flow rate by purity / residual oxygen content (1)