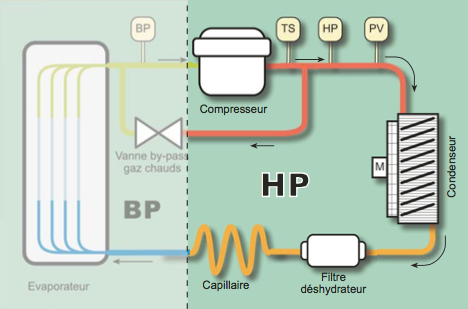

Here is the second part of our series. This month, we will focus on the high pressure part of the circuit, between the compressor outlet and the expansion.

The high pressure circuit.

Here are mainly safety and regulatory bodies.

The first one shown in the diagram is the safety thermostat (TS). It stops the refrigeration unit if the discharge temperature exceeds approximately 100 ° C. This can occur in the event of a lack of gas, overload, or a deregulation of the condensing temperature.

The 2nd safety device is the high pressure switch. (HP). It stops the group in the event that the circuit is overloaded (too high ambient or compressed air temperature, undersized dryer, dirty condenser, fan malfunction ...)

These 2 safety devices have a manual reset button which allows you to acknowledge the fault - not before having identified the cause and having remedied it.

For regulation is the fan pressure switch. (PV) whose role is to maintain a pressure - and therefore a temperature - of condensation in the range established by the manufacturer by regulating the operation of the fan. This pressure switch has 2 settings, the intervention point and the differential. The gas pressure is brought in by a capillary (which can be seen in the lower part on the photo on the left). For the water-cooled versions, this pressure switch is replaced by a thermostatic valve (on the water circuit), adjusted to obtain a determined condensing pressure.

Just before the capillary is the filter drier, the role of which is to remove traces of moisture and solid or acidic pollutants possibly present in the refrigerant gas circuit. Finally, the capillary marks the HP - BP border. This tube, of very precise diameter and length, helps to relax the gas and produce the amount of cold necessary.

Simple controls

After checking the correct operation of the refrigeration unit (see our previous edition), checking the operation of the fan is the 2nd step. All our ACT dryers are fitted with a regulation pressure switch. The fan must therefore periodically start and stop once the desired pressure has been reached. This can range from a few seconds to several tens of seconds depending on the amount of gas, the charge rate, the ambient temperature .... When a group heats up, the fan does not start, the dew point is too high , a refrigerant gas leak is almost certain.

Faults or malfunctions on the high pressure part are almost always due to an overload of the refrigeration circuit. If the dryer restarts after resetting the H.P. pressure switch, the cause of the overload must be determined (temperatures, fan malfunction, condenser cleaning, etc.)

When the shutdown is caused by thermal safety, the reasons may be those mentioned above, but also a gas leak or too low a setting of the condensing temperature. (Pressure switch or thermostatic valve adjusted or faulty) This safety device must therefore not be reset repeatedly, otherwise the refrigeration compressor will be irreparably damaged. A control of the refrigeration pressures is necessary before continuing. . .