Contrary to appearances, a filter element for line filter is much more than just a consumable. Its manufacture must be rigorous and the choice of filter media of the highest quality if we want to obtain the claimed performance.

A good element must resist not only all lubricants for compressors but also a sufficient differential pressure so as not to disseminate its various constituents in the network. The assembly resins must also be ultra-resistant and inert towards compressed air pollutants. The dimensions and the seals must provide a perfect internal seal to avoid any passage of untreated air downstream of the filter.

The ISO 8573-2 standard defines the criteria for the effectiveness of filters, in particular for particles and for the residual oil content.

The WALKER adaptable filter elements, which we have been distributing for more than 10 years on the national territory, guarantee those of the original filter elements and, of course, compliance with ISO 8573-2.

So saying it is good, but proving it is even better.

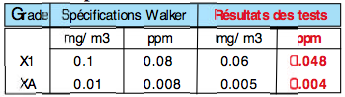

The filter elements of grade X1 and XA have been tested by an independent laboratory in order to certify the announced performances in terms of oil removal.

The test procedures were implemented according to method B1 of ISO 8573-2: 1996. The excellent results are shown in the table opposite.