In compressed air, the role of the silencer is to reduce the noise level of the exhaust to an acceptable level for the environment and people. Notwithstanding the performance requested, the safety criterion is essential in order to avoid serious injury to personnel or damage to the immediate environment.

Indeed, the muffler connected to a pneumatic system, must resist a differential pressure as brutal as sudden when escaping the compressed air. When the silencer is of good quality and has been correctly dimensioned, the problem does not arise - at least during commissioning. Because over time, the muffler will gradually clog up and its pressure drop will naturally increase.

This means that the instantaneous flow through the muffler will be slowed down and the pressure inside the body will increase as the operating time increases. If the maintenance department does not pay attention to it and does not replace the muffler - or the media - in good time, this pressure will reach the breaking point and the muffler will burst, violently projecting debris around it.

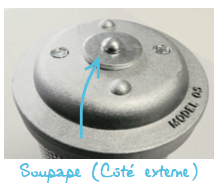

This is where the safety valve becomes important. It will prevent the muffler from bursting by letting the air escape and, by increasing the exhaust noise, will alert the user audibly to the need to replace it.

Of course this safety comes at a price, and valve mufflers are slightly more expensive. But that is nothing like the damage and injuries avoided.

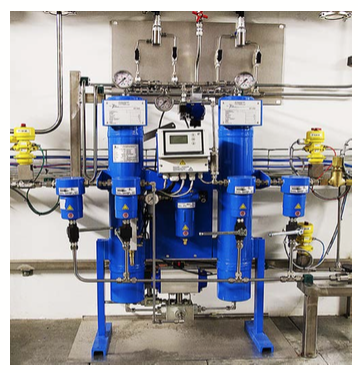

All our silencers are fitted with an anti-burst valve.

Remember to make aware your customers when choosing or replacing exhaust mufflers.