A complete range from 20 to 9000 m3 / h. GPV series refrigeration dryers actively participate in companies' ISO 50.001 energy saving policy thanks to specifically selected refrigeration units:

A complete range from 20 to 9000 m3 / h.

GPV series refrigeration dryers actively participate in companies' ISO 50.001 energy saving policy thanks to specifically selected refrigeration units:

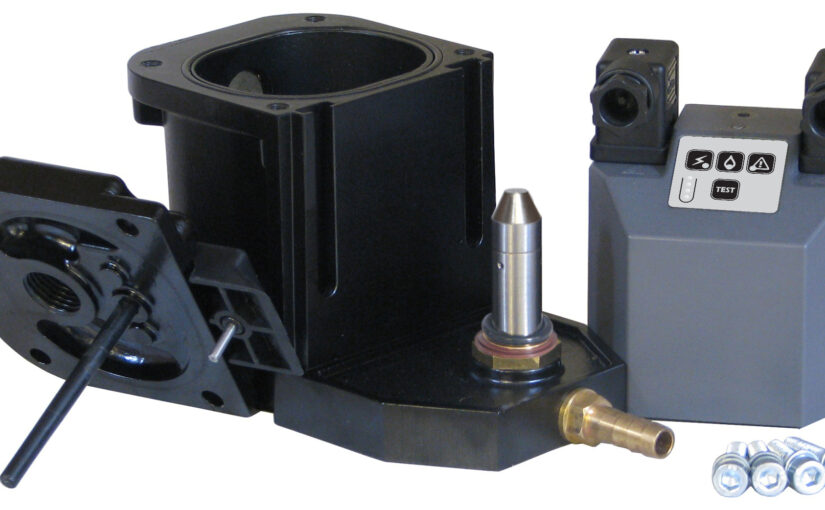

- Variable speed refrigeration compressor

- Variable speed condensing fans

- Electronic expansion valve

- Steam traps without loss of compressed air

Opposite is a GPV 600 dryer (with a flow rate of 3600 m3 / h) in place in a mechanical production plant. The fluctuating charge rates allow a significant reduction in operating costs, judge instead:

For a treated air flow of 2500 m3 / h (70% of its capacity) the electric consumption decreases by 42% (which corresponds to a saving of 0.22 € / hour of operation.) This calculation is based on nominal temperatures (35 ° C compressed air and 25 ° C ambient). As soon as the temperature drops by 5 ° C (30/20 instead of 35/25) the savings reach 56% (29 cents savings / hour). Or about € 2,500 in savings / year for a kWh at 8 cts.

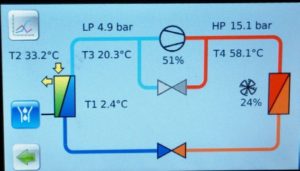

GPV dryers are equipped with a color touch controller displaying all operating parameters as well as the savings achieved. Do not hesitate to contact us to establish an energy balance of these dryers according to the operating parameters of your customers.

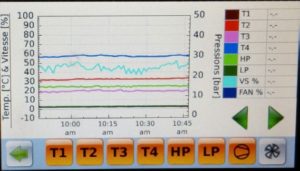

Control of dryer activity and savings

Recording of the evolution of the parameters in real time.

Real-time block diagram of the cold circuit.