Here is a recurring question, both from users and distributors.

Before providing an answer, there is none ready made, let’s consider the factors and pollutants that will degrade the desiccant and therefore shorten its lifespan.

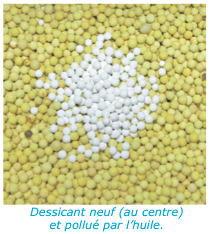

Oil from the compressor : It is the major pollutant. A good filtration is imperative here to protect the desiccant. The oil is adsorbed by the desiccant but is not evacuated during regeneration. It gradually saturates the desiccant - which takes on a yellowish tint (see photo). The dew point degrades over cycles, the replacement occurs prematurely.

Water in liquid phase : A sudden arrival of liquid water will literally "drown" the desiccant, hence the need to monitor the proper functioning of traps daily.

Depending on the load rate of the installation, the desiccant can no longer be regenerated by the dryer, replacing it should be immediate.

The speed of passage of compressed air through the tank. There is a critical speed that should not be exceeded - or even reached - called the fluidization speed. This critical speed causes the desiccant balls to rise, which roll and rub against each other. The resulting attrition causes a large amount of dust (prematurely saturating the dust filter) and the reduction of the load in the tank. This phenomenon appears when the dryer is undersized (pressure drop, large air demands, growth in network needs ...) or when the network is pressurized too quickly.

Operating pressure : On a dryer without heat, each tank is depressurized every 4 to 5 minutes. The shock to the desiccant is all the more important the higher the working pressure. Wear and tear mechanical will obviously be faster at a pressure of 13 bars than at a pressure of 7 bars.

The periodic visit. Pressure vessels must be examined by the competent authority every 40 months and re-qualified every 10 years. During these operations, the desiccant must be emptied to allow inspection. It is a good opportunity to check its appearance and / or, especially in small quantities involved, to fill the tanks with new desiccant.

In summary, although on paper the desiccant has a lifespan in tens of thousands of hours, we see here that the factors of use and exploitation take precedence over theory. In practice, barring accidental pollution, a visit to the tanks is an ideal time to proceed with the replacement. On installations where large quantities are involved, a humidity measurement or a sample analysis may be requested to determine if replacement is required.