Designed to meet the latest quality requirements for compressed air filtration, this new range of filters includes 19 threaded models - supplemented by 8 flanged models - allowing flow rates up to 25,500 m3 / h.

Up to 3 "(2550 m3 / h) all foundries are made of die-cast aluminum covered with polyester paint offering an impeccable finish.

Foundries are protected internally and externally by an E-Coat ™ treatment offering protection against corrosion, the resistance of which has been tested according to ISO standard 9726: 2006 (Corrosion tests in artificial atmospheres - Salt spray tests)

Their mechanical resistance far exceeds the requirements of the directive for pressure equipment. Thus, with a coefficient of 5 (Burst pressure greater than 80 Purge - PARTENAIRbars) their robustness far exceeds that of competitive filters with conventional foundries.

The purge orifice is tapped in 1/4 "to facilitate the installation of external traps (E.V. or level detection)

The new filter media, hydrophobic and oleophobic, opt for the deep filtration technique and offer an optimum efficiency / pressure drop ratio. Sealing is now ensured by two O-rings.

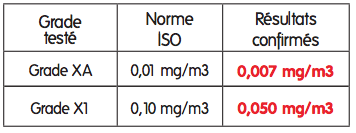

The performance of these filters has been tested and validated by an independent body.

They were far beyond the values imposed by standard 8573-1: 2001

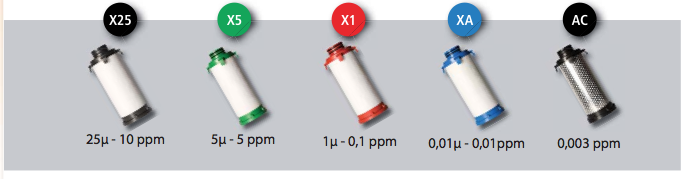

5 filtration grades are available. The filter elements keep the color code specific to Walker to avoid any misunderstanding during maintenance operations.